|

The non-traumatic placement of crown margins is one of the most important parameters for the periodontal health of a restored tooth. Previous studies have shown that subgingival restoration margins may lead to a more or less severe inflammation of the marginal periodontium. However, it is often impossible to place a restoration at supragingival level, due to the defect morphology and, especially in the anterior area, for esthetic reasons. In such cases it is necessary to place the restoration margin in a non-traumatic way without damaging the periodontal itssue. In cooperation with Prof. Günay of the Medical Academy in Hanover, Komet has developed an instrument Kit for crown preparation which includes instruments with guide pin designed to meet these requirements: Kit 4384A includes several diamond instruments with uncoated guide pin (P = Pin) in the shapes tapered round and torpedo tapered, in medium grit for shaping and fine grit for finishing. These instruments with guide pin can create a margin depth of 0.6 mm (size 018) or 0.8 mm (size 021) The congruent instruments without guide pin are disigned to increase the cutting depth in case of all-ceramic or veneer crowns. The egg shape is intended for palatinal or lingual reduction in case of capping anteriors. We recommend the use of an Arkansas stone for finishing and rounding edges, corners and angles (if necessary also to create smooth marginal surface). A prerequisite for a successful tissuefriendly crown preparation is a sound periodontium which, if necessary, may be achieved through a systematic periodontal therapy to be completed beforehand. Advantges :● Guide pin as "horizontal distance keeper" : For circular material reduction the guide pin guarantees controlled preparation with an even cutting depth. This way a uniform preparation is created, avoiding the "gutter" effect. Controlled preparation of a defined crown margin● Guide pin as "vertical distance keeper": During the preparation of a subgingivalmargin the 0.5 mm long guide pin assures that a pre-defined distance to the periodontium is kept. Damage to the biological width* (the area at the coronal side of the |

|

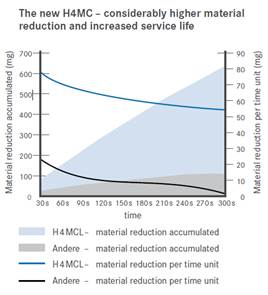

Designed for cutting all commonly used metal alloys, titanium and veneers made of low fusion ceramics. Product characteristics and advantagesDue to its special D-toothing, the H4MC facilitates quick and efficient cutting of crowns and bridges made of conventional metal alloys. large chip spaces allow quick chip removal and prevent clogging, especially when cutting soft alloys with gold content. The H4MC is equally suited for ceramic veneers. A further distinctive feature is the tiptransversing blade permitting easy penetration into the material to be cut. The pyramidshaped blade design prevents Blade breakouts and guarantees increased stability and high resistance to breakage, thus ensuring a smooth operation with little vibration. Compare to all other crown cutters on the market, incl. copies made by the competition, the H4MC (working part comes in various lengths, see reverse: H4MC - H4MCXXL) features a consistently higher material reduction rate. These cutters prove particularly efficient in case of hard-to-cut non-precious metal alloys such as Dentitan. The instruments can be used in the micromotor as well as in the turbine.  Indications :The H4MC can be indentified by its white and black rings (white for ceramics, black for metal). Crowns should be cut in several steps, i.e. the procedure is carried out in intervals in order to cut only a small area each time. Ceramic veneers should be cut with the Tungsten Carbide crown cutter H4MCL.314.012 (fig. 1). Metal crowns are to be cut with crown cutter H4MCL.314.012 (fig. 2).  Recommendations for use :● optimal speed: 160.000 rpm in the micromotor. ● In case of materials that tend to "jump", (e.g. certain non-precious metal alloys), we recommend the use in the turbine, applying low contact pressure. ● In order to make full use of the capacity of the instrument's working part during the cutting phase, we recommend to apply the instrument at an angle of approx. 45° to the crown. ● Always make sure that sufficient coolant is applied (at least 50 ml/min.). ● Do not exceed a maximum contact pressure of 2N.  |

|

In cooperation with Dr. Radlanski, Freie Universität Berlin, the AGK burs have been developed as specialist instrument for removing adhesive residues. The instruments are able to remove the soft adhesive quickly and, thanks to their special toothing, without damaging the hard enamel. At low contact pressure, the instruments operate with low vibration and achieve perfectly smooth surface while generating merely a minumum of heat. This possible thanks to the innovative blade geometry. The twisted blades made of durable tungsten carbide are optimally suited for precise reduction of soft materials and assure smooth operation and high treatment comfort. In order to avoid the risk of damaging the gingiva, all adhesive removers are provided with smooth, non-cutting tips (tip without blades). Moreover, the safety chamfer at head end eliminates the formation of grooves. The tapered adhesive remover is available for the contra-angle and the turbine in 2 head lengths (4.75 mm and 8.00 mm). The long version - the H22ALGK - is specifically designed for canines and longer anteriors. The egg - shape (H379AGK) and the grenade-shape (H390AGK) are specially suited for palatinal reduction of adhesive in the lingual technique. Clinical sequence :1. Pre-operative situation 2. Removing orthodontic brackets 3. Brackets removed from tooth 11 4. Removing the adhesive residues with H22ALGK.204.016 5. Palatinal removal of adhesive residues with H379AGK.204.023 6. Polishing the labial tooth surfaces with prophylaxis polisher 9631.204.060 .  Recommendations for use :● The adhesive removers are used without pressure. Always supply plenty of water coolant (at least 50 ml/min.) ● Recommended speed for shank 314: - Use in the red contra-angle at 120 000 rpm - Use in the turbine at 160 000 rpm ● Recommended speed for shank 204: - Use in the micro-motor / contra-angle at approx. 40 000 rpm Apart from this general information, please observe the individual speed indicated on the packaging. The instruments must be used with utmost care to avoid damage to the dental enamel. After complete removal of the adhesive the enamel will be shiny. |